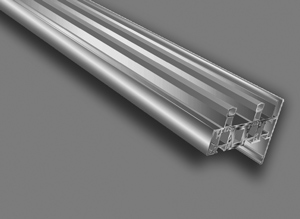

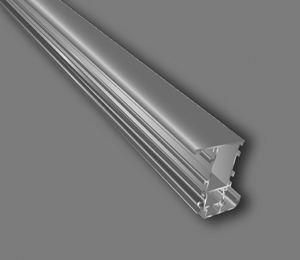

FW1-50 Series curtain wall is developed by focusing on three main areas, such as cost, safety and speed of fabrication and installation. Some of the advanced features it offers are by using a latch system for the glass, which self-fixes to the frame giving a breakthrough in curtain wall technology. It avoids the use of temporary pressure plates and screws to hold the glass when set into place. We have designed a transom connector that carries more weight and can be installed from inside or outside the structure giving more speed for installation. The system offers the use of EPDM rubber pads to isolate in between transom and mullion sections which forbids noise, resulting from daily contraction and expansion. EPDM front gaskets are fixed as well before the structural silicone which prevents water leakage in case the silicone is not well filled. A specially designed teeth plates to fit on our pre-made wall brackets to speed-up the installation process allowing easy movement to correct the alignment of the glass panels. We have designed a snap-on pressure cover section for the conventional type that avoids the use of fixing screws, which makes the installation fast and easy.

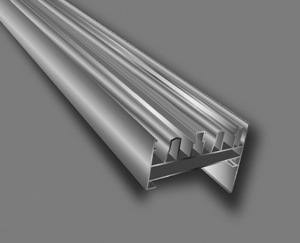

FW1-70 Series offers the use of a special locking clip to hold the glass in 4-way structural system. A glass fixing support is also used in addition of structural silicone to strengthen the fixation. This protects the glass sheet from falling down and at the same time increases its lifetime ex- pectation to twice as long. The system offers the use of EPDM rubber pads to isolate in between transom and mullion sections which forbids noise, resulting from daily contraction and expansion. EPDM front gas-kets are fixed as well before the structural silicone which prevents water leakage in case the silicone is not well filled.

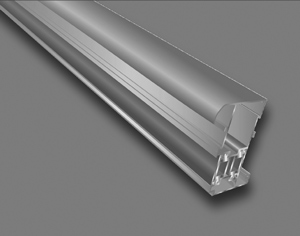

FW1-85 Series is our newly developed mechanical unitized curtain wall system, without silicon bonding which gives more assurance for longer lifetime guaranty and easier replacement of glass in the future. The profile sections are designed to meet the different degrees of segmentations of the glass panel by having selections of adaptors depending on the project requirements, and this creates flexibility in convenience with circular designed buildings and structures. The system is using EPDM rubber to resist hot temperature and weather variations. There are designated brackets attached to every unit for lifting during the installation process. We have designed a special hook that compliments the bracketing system on every slab.

SL-120 Series is our most advanced sliding thermal break system. The internal and external profile sections are designed to be connected without the use of continuous crimping. It can be connected manually with the use of special internal polyamide connectors which are distributed equally then tightly fixing it with an external continuous polyamide strip. These connectors are the main key to meet the ESTIDAMA requirements. With our advanced air system rest assured that the full thermal performance will be reached by ensuring there will be no air leakage.

SL-114 Series is designed and constructed using the highest quality materials to produce a smooth sliding system that compliments each home or office where it’s used. This offers an effective and useful feature such as the use of epdm flocking gaskets which helps the shutter slide easily. Having dual weather seals at the top, bottom and sides provide the benefits of dust elimination and air tightness. The system offers the use of high quality hardware, accessories and a water drainage system.

H-100 Series is our most advanced hinged thermal break system. It offers the same features with SL-120 Series by making the design of the internal and external profile sections to be connected without the use of continuous crimping. This procedure makes the assembly faster and saves time by avoiding the use of machines. The special feature of this system is the concealed type hinge accessory that makes the assembly fully tight sealed. Using the same special internal connectors and external continuous polyamide strip meets the ESTIDAMA requirements. ESC doors and windows are safe, secure, easy to operate and we offer the choice to use laminated or tempered safety glass with Low E insulated for improved performance.

H-63 Series is one of our hinged thermal break system which is designed in the traditional way. The section profiles are supported with a wide range selection of high quality hardware and accessories. the system is using epdm rubber to resist hot temperature and weather variations. With our advanced air system, rest assured that the full thermal performance will be reached by ensuring there will be no air leakage in the home or office.

H-45 Series offers the highest quality of materials used from production to installation, together with the use of high performance EPDM rubber gaskets that eliminate air, dust and water penetrations. The system of- fers a wide selection of high quality hardware and accessories. We have designed a one-click safety latch accessory that keeps the doors and windows shut and closed even without applying the locking mechanism of the handle. The section profiles are also supporting the use of the tilt and turn window mechanism.

We have developed the F-66 Series folding system to create a large open spaces for both home and office requirements, with no unsightly inter- mediate vertical frames to obstruct the opening. With endless possibilities, the multi-fold door makes the room look bigger, making living space more flexible. the system is secure, durable and has a slim type of perimeter frame. There are numbers of different configurations available for selections to suit the client’s requirements. With security glass and a secure frame, these aluminium bi-folds are virtually maintenance free and built to last.

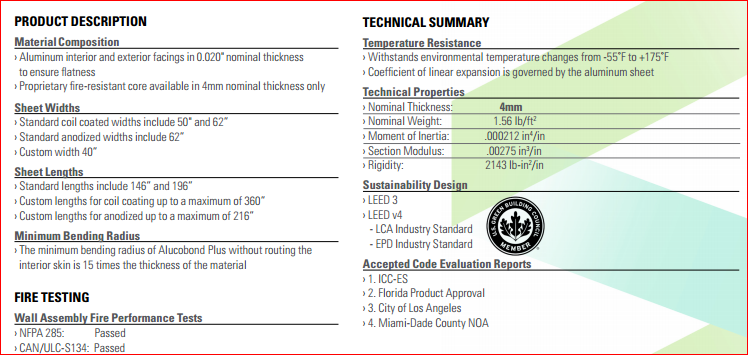

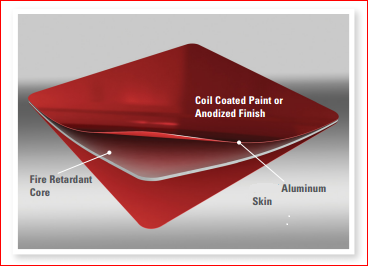

Fire retardant {FR} aluminium panel certified by BM Trada meets the ASTM E84 Grade A/1. Due to the usage of a modified mineral core between the aluminium skins. Combined with horizontal fire stops to be used with our curtain wall systems ESC ensures its buildings. Safety are top priority and in line with new safety rules in Dubai 2016.

It has good impact resistance, toughness and bending rigidity. It will not be damaged or abraded by sand. The latest American and European coating technology enables us to produce a variety of colors of choice. Manufactured using the most advanced equipment and strict quality control gives the panel excellent. Torsion strength and bending strength under heavy loads and is lightweight at only (3.5-5.5kg/m2)