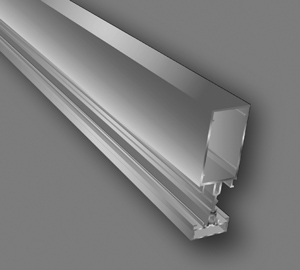

FW1-70 Series offers the use of a special locking clip to hold the glass in 4-way structural system. A glass fixing support is also used in addition of structural silicone to strengthen the fixation. This protects the glass sheet from falling down and at the same time increases its lifetime ex- pectation to twice as long. The system offers the use of EPDM rubber pads to isolate in between transom and mullion sections which forbids noise, resulting from daily contraction and expansion. EPDM front gas-kets are fixed as well before the structural silicone which prevents water leakage in case the silicone is not well filled.

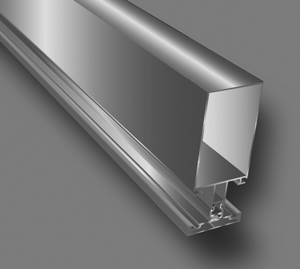

FW1-50 Series curtain wall is developed by focusing on three main areas, such as cost, safety and speed of fabrication and installation. Some of the advanced features it offers are by using a latch system for the glass, which self-fixes to the frame giving a breakthrough in curtain wall technology. It avoids the use of temporary pressure plates and screws to hold the glass when set into place. We have designed a transom connector that carries more weight and can be installed from inside or outside the structure giving more speed for installation. The system offers the use of EPDM rubber pads to isolate in between transom and mullion sections which forbids noise, resulting from daily contraction and expansion. EPDM front gaskets are fixed as well before the structural silicone which prevents water leakage in case the silicone is not well filled. A specially designed teeth plates to fit on our pre-made wall brackets to speed-up the installation process allowing easy movement to correct the alignment of the glass panels. We have designed a snap-on pressure cover section for the conventional type that avoids the use of fixing screws, which makes the installation fast and easy.